PCB PROFESSIONAL MANUFACTRRER!

PCB PROFESSIONAL MANUFACTRRER!

ISO9001, ISO TS16949 and UL certified factory, producing RoHS compliant PCB products.

Optimized supply chain management ensures the quality of raw materials and on-time delivery.

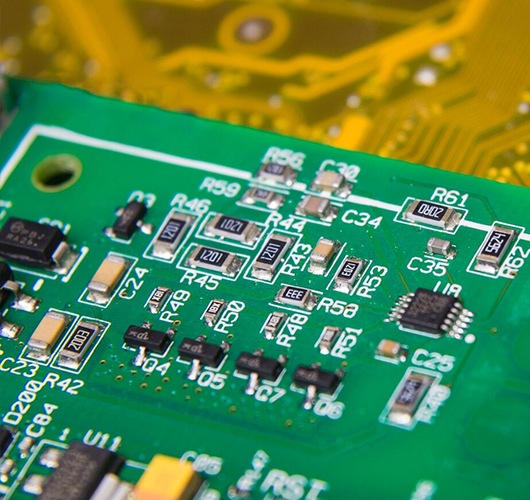

Advanced automated production equipment has greatly improved production efficiency and product quality.

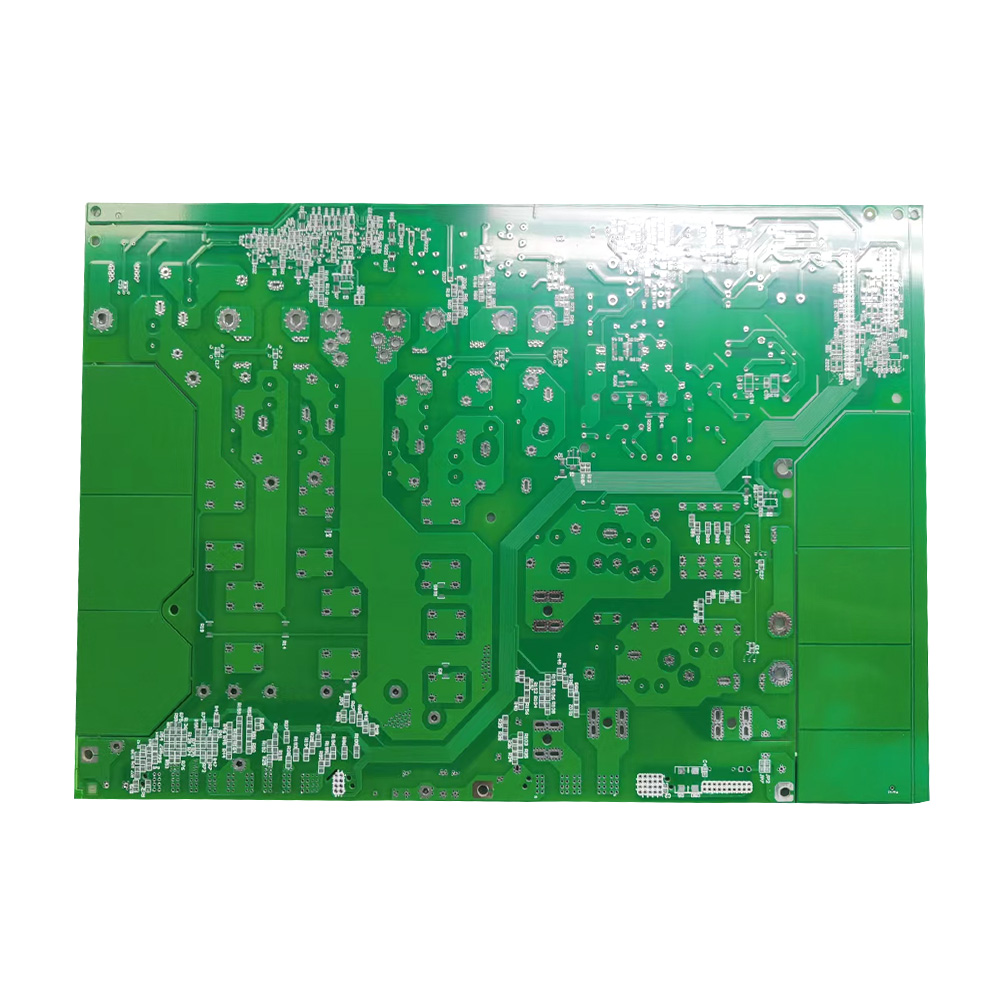

Complete production lines to complete all printed circuit boards within the factory.

More than 12 years of experience in printed circuit board production.

Experienced professional engineers are responsible for production management and provide professional suggestions for reducing costs and improving quality.

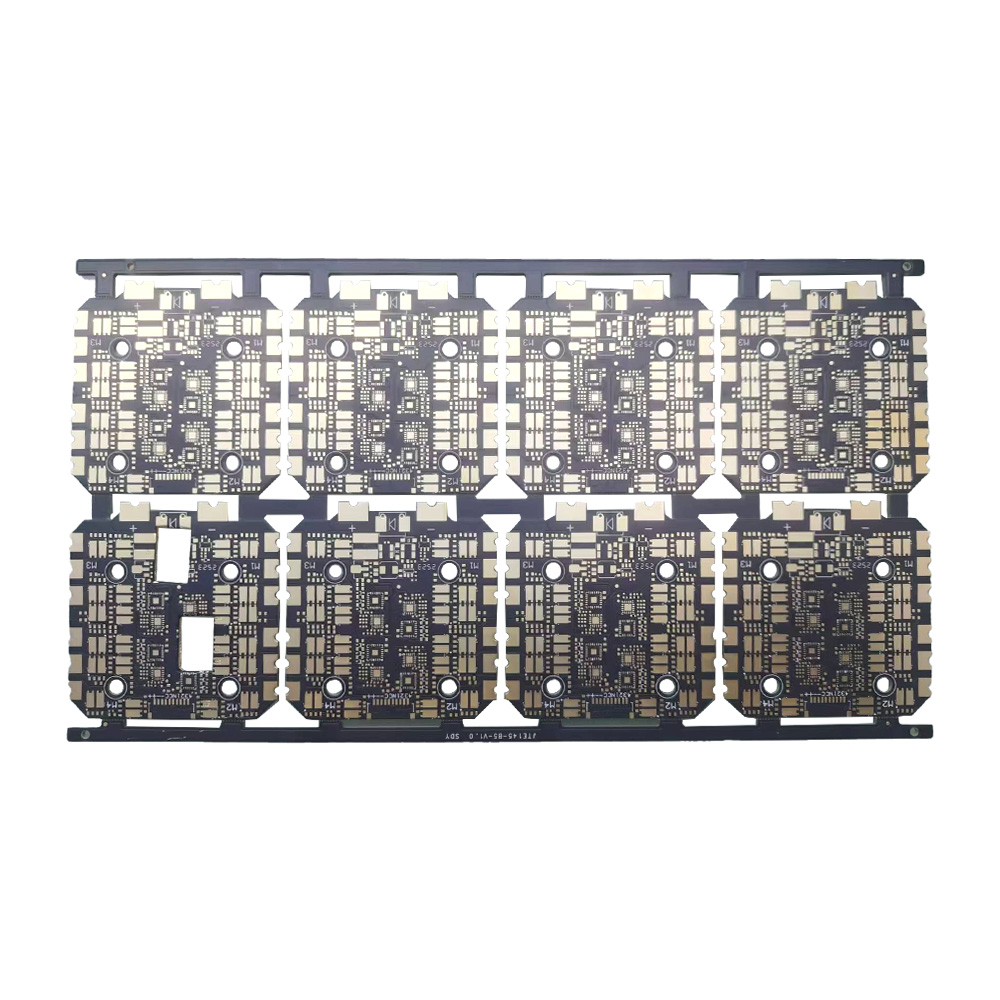

Quick turnaround, multi-project small and medium-sized production services.

All-round technical support from design to production and shipment.

Responsible for after-sales service feedback to customers.

Products are widely used in computers, data communications, industrial and industrial instruments, automobile manufacturing, consumer electronics, telecommunications, medical equipment, military and aerospace fields, etc.

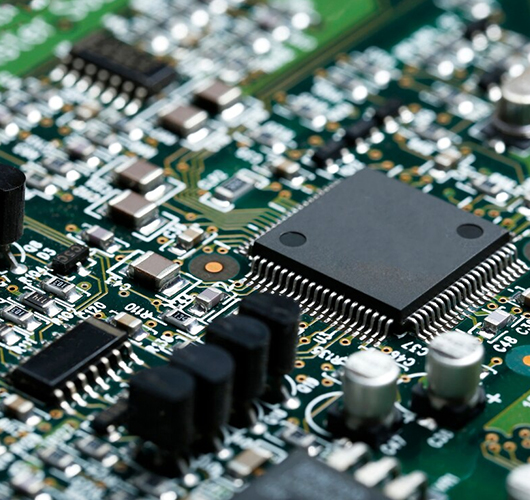

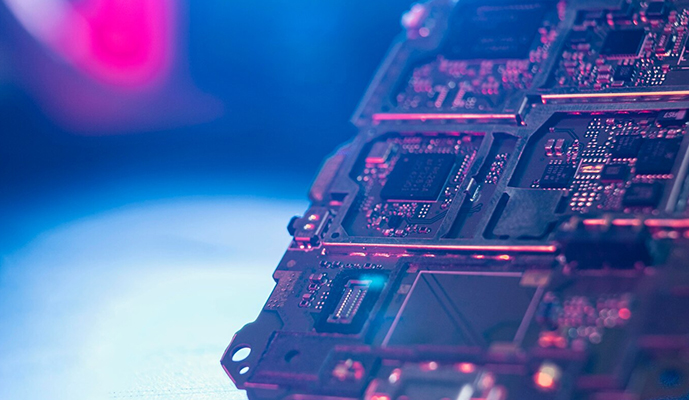

The motherboard is the physical carrier of all the hardware in a computer (such as CPU, memory, graphics card, hard disk, etc.), and it connects the hardware through slots (such as CPU slots, memory slots) and interfaces (such as PCIe, SATA, USB)

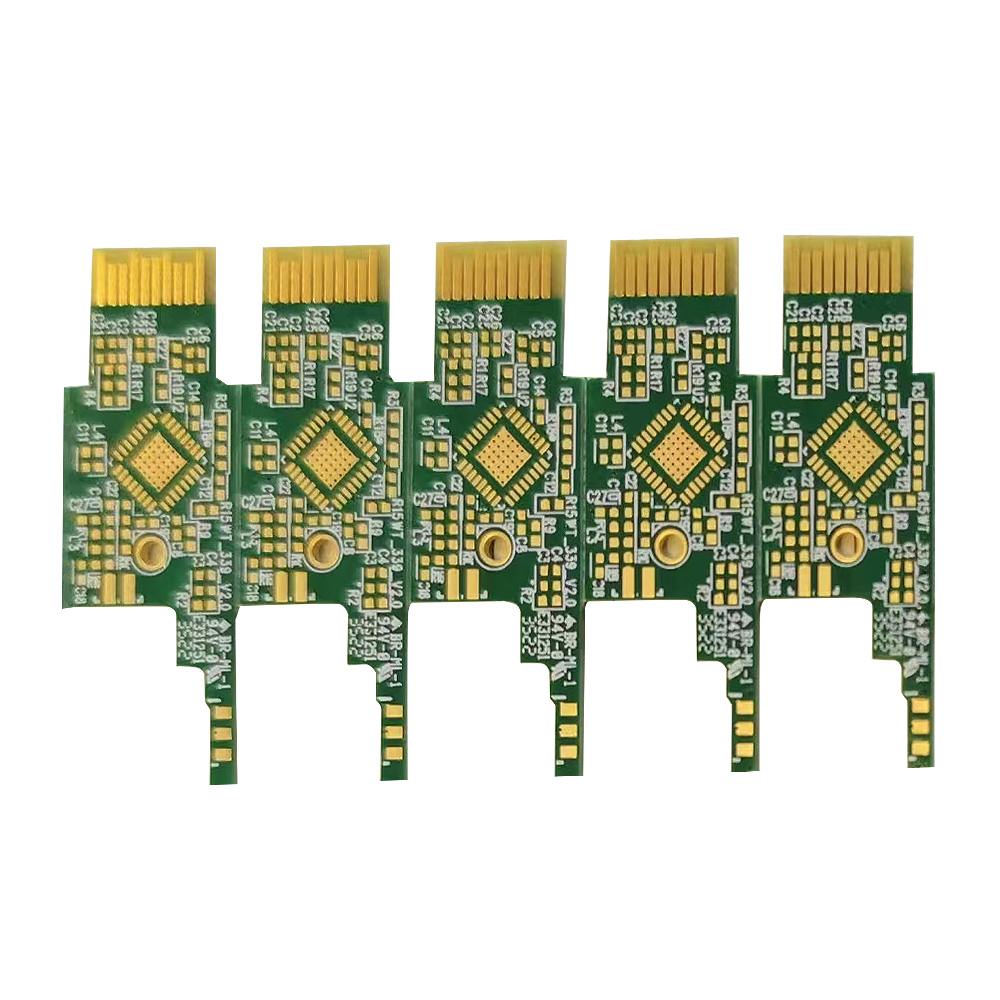

It is widely used in telephone exchange systems, satellite communication equipment, high-speed routers, commercial telephone technology, VoIP (Voice over Internet Protocol) devices, etc., which need to adapt to high-frequency signal transmission and require low dielectric loss and stable impedance control. High dielectric constant (Dk) materials are often adopted

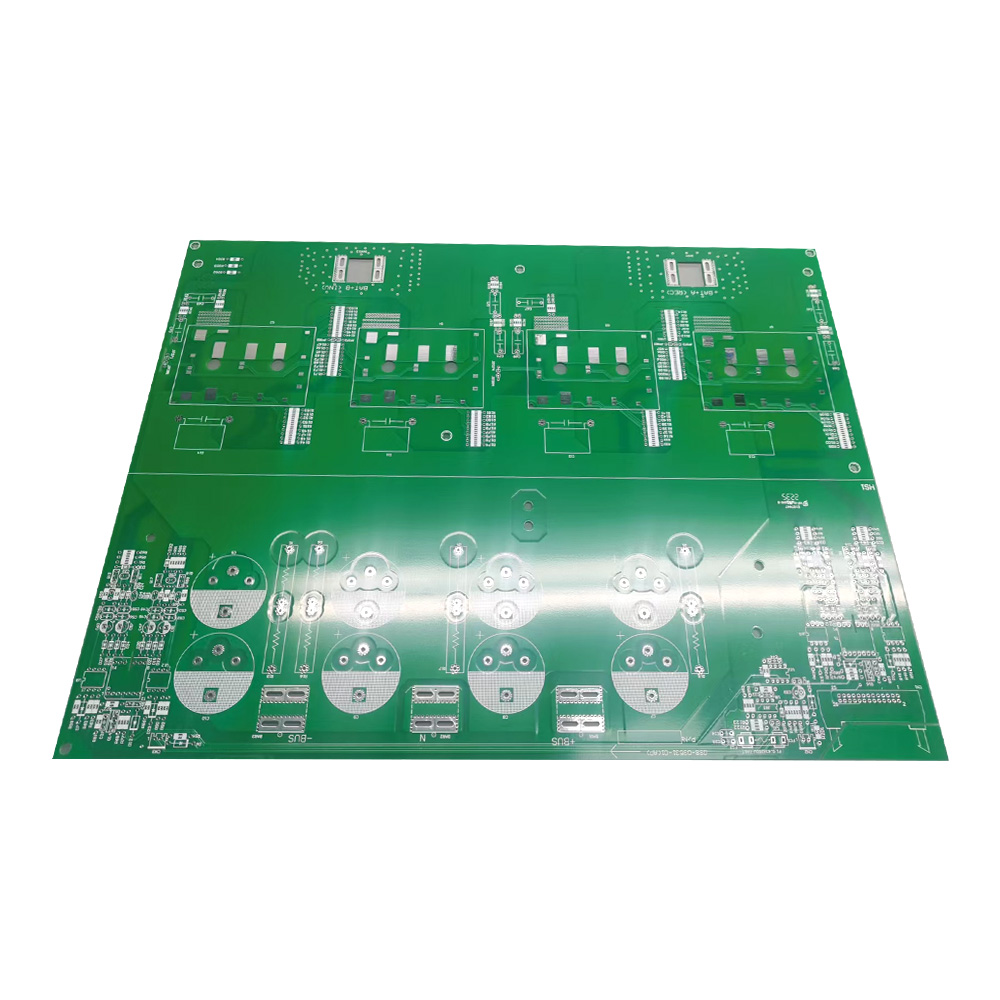

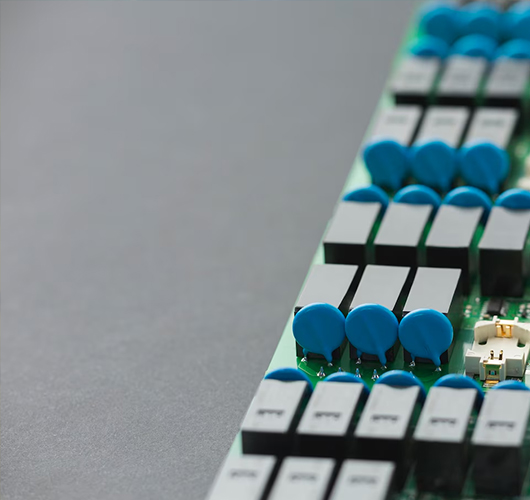

New energy equipment such as photovoltaic inverters and energy storage systems have extremely high requirements for the power carrying capacity and heat dissipation performance of PCBS. The selection of special heat dissipation plates and the combination of Layout wiring optimization significantly enhance the reliability and service life of photovoltaic inverter PCBS

Printed circuit boards specifically designed for automotive electronic systems undertake the functions of connecting electronic components, signal transmission and power consumption control. They have extremely high requirements for reliability and stability and are thus hailed as the "boards of life".

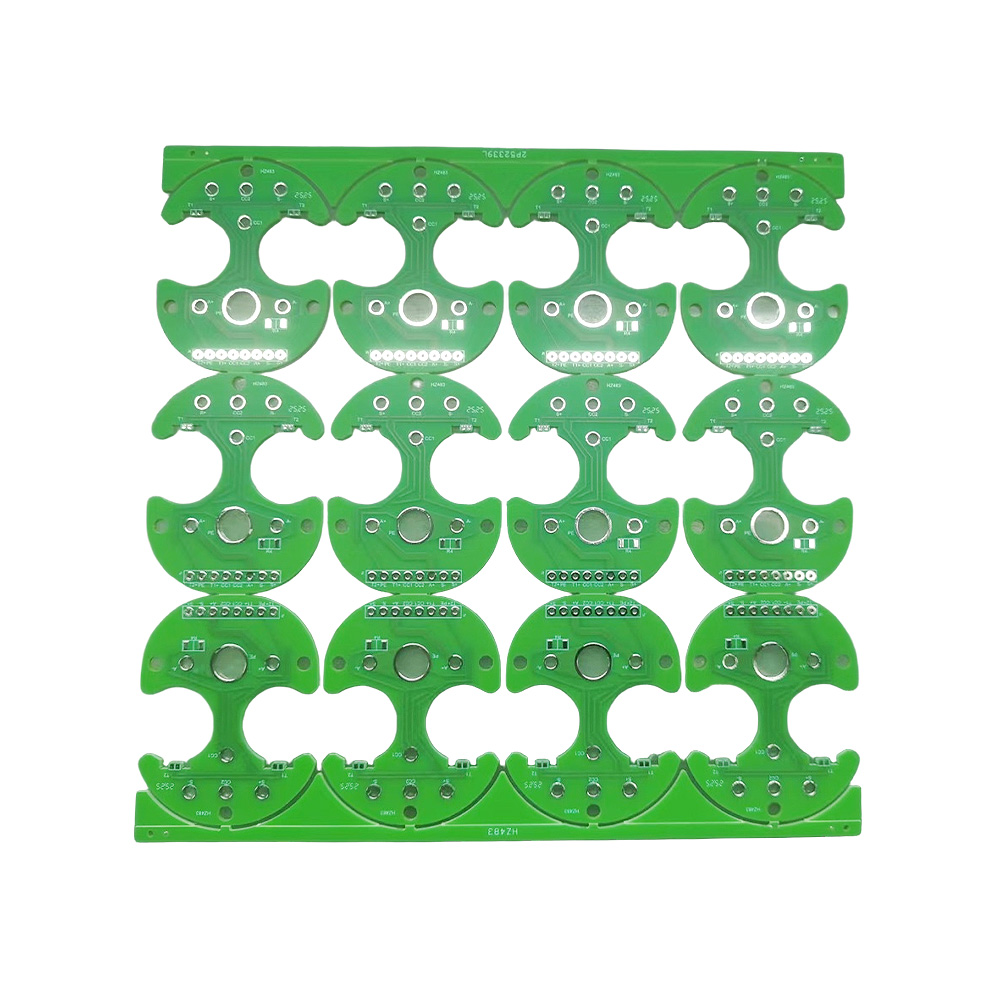

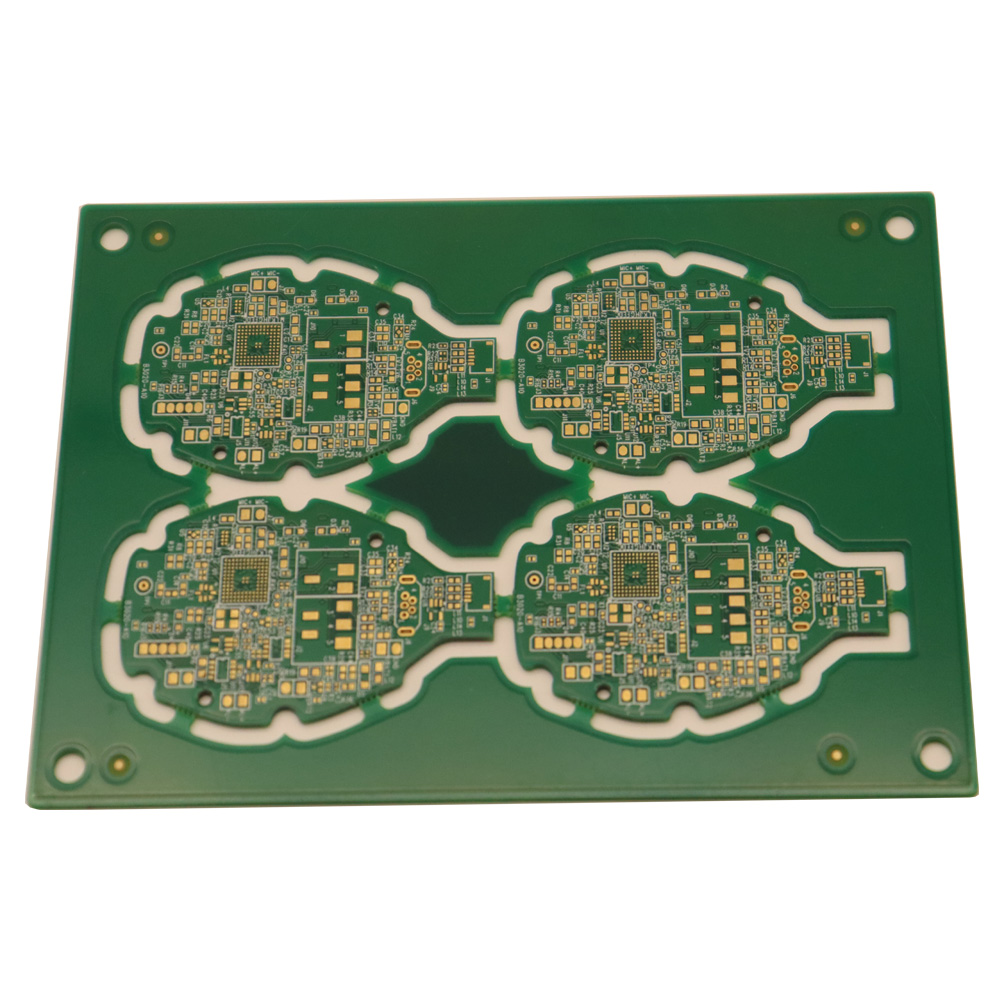

Consumer electronics tend to be miniaturized, and the space utilization rate needs to be optimized through high-precision circuits (line width/spacing ≤0.1mm) and micro-hole technology (hole diameter ≤0.15mm)

The electromagnetic environment in hospitals is complex. PCBS need to be designed to withstand high temperatures, humidity and interference. Most PCBS adopt plating/gold plating processes to ensure product stability

The PCB for unmanned aerial vehicles features high reliability, high-density interconnection, high-frequency signal processing and lightweight. From the selection of covering materials, multi-layer structure, thermal management, electromagnetic compatibility, high-frequency design to customized processes, all are meticulously designed

Purchase first

Pay later

Purchase first

Pay later

Purchase first

Pay later

Purchase first

Pay later

Purchase first

Pay later

Purchase first

Pay later

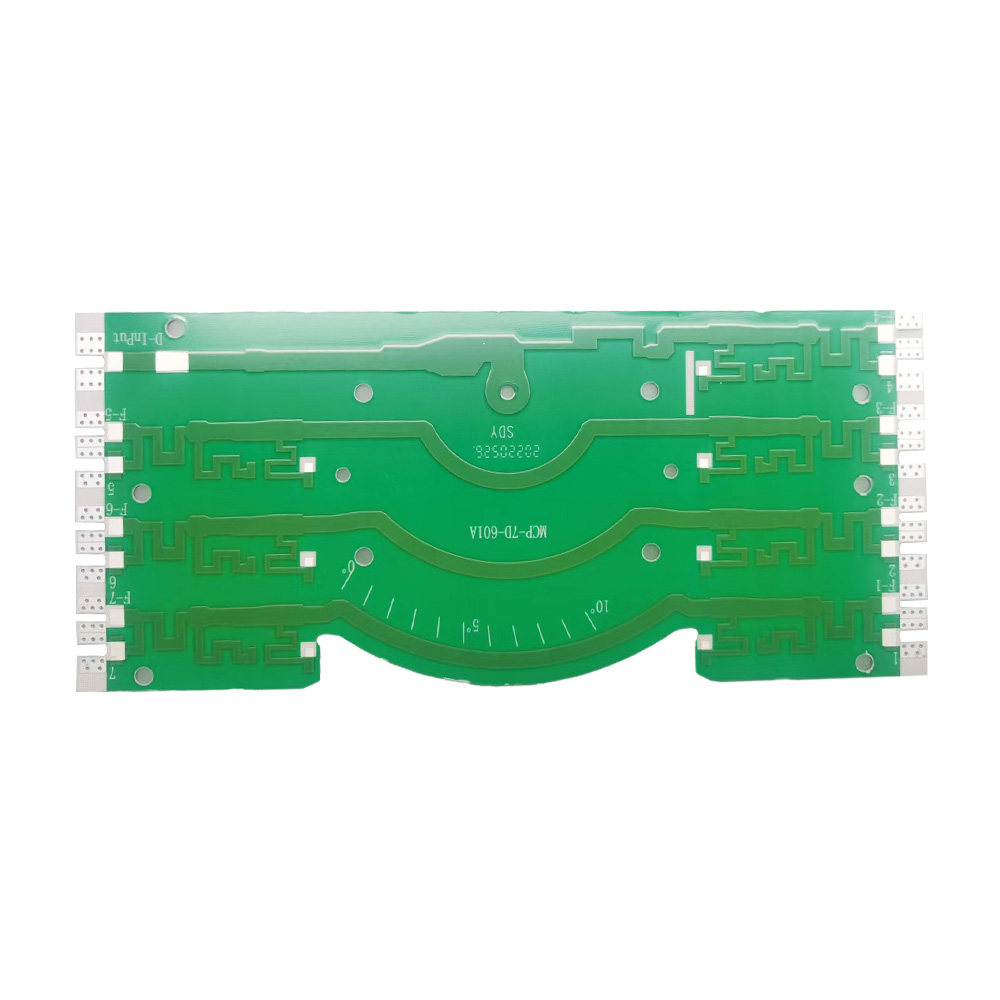

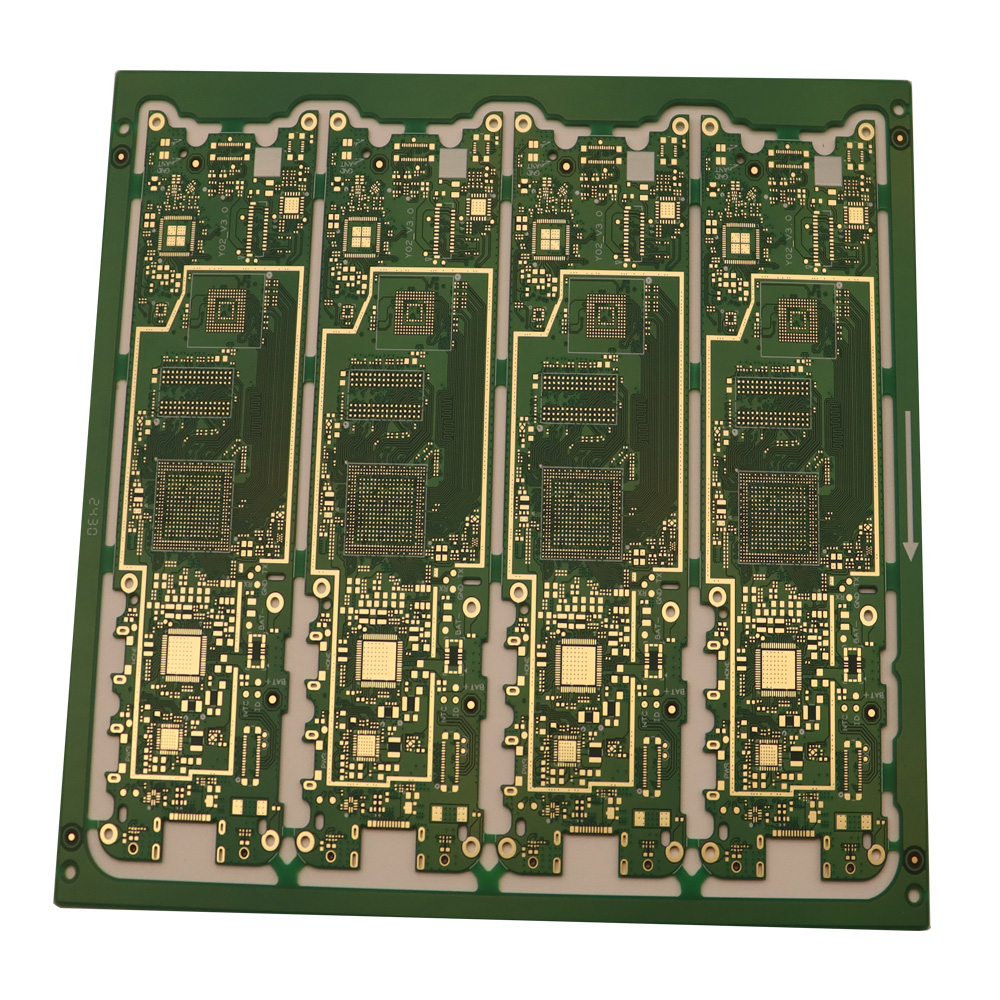

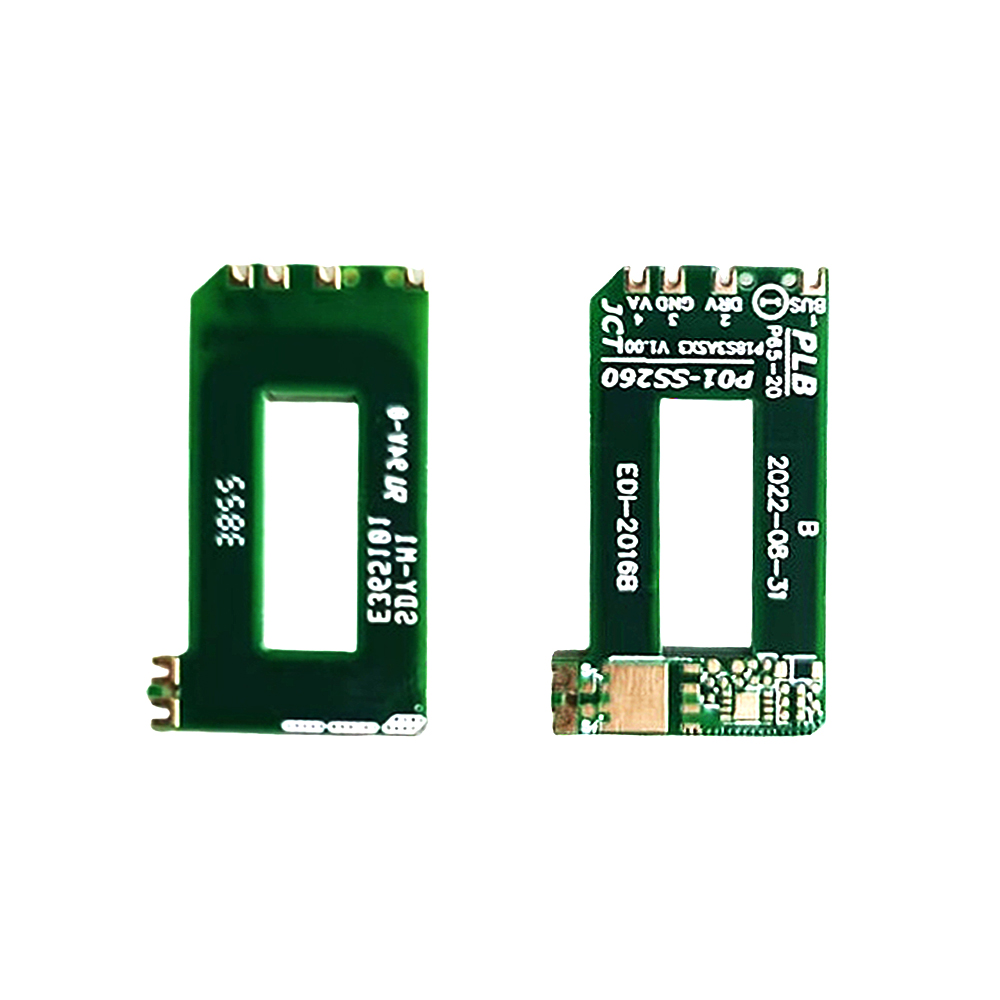

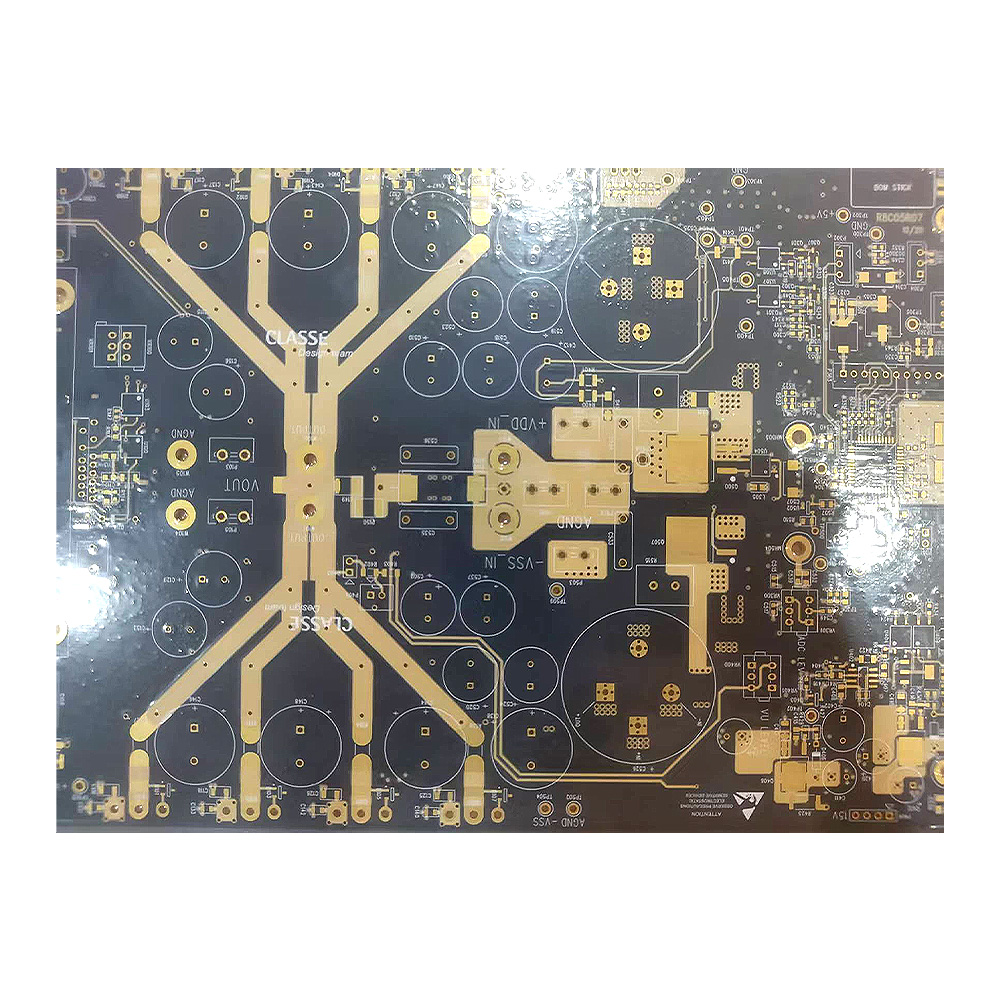

Shenzhen Sendwin Electronics Co.,LTD. / Dickson Circuits (Shenzhen) Co.,LTD. was established in 2010, the company's main products are: double-sided and multi-layer high-precision, high-difficulty printed circuit boards (including SD MMC card thin board, carbon film board, impedance board, etc.), monthly production capacity of 110,000 square meters

ISO9001, ISO TS16949 and UL certified factories, producing RoHS compliant PCB products.

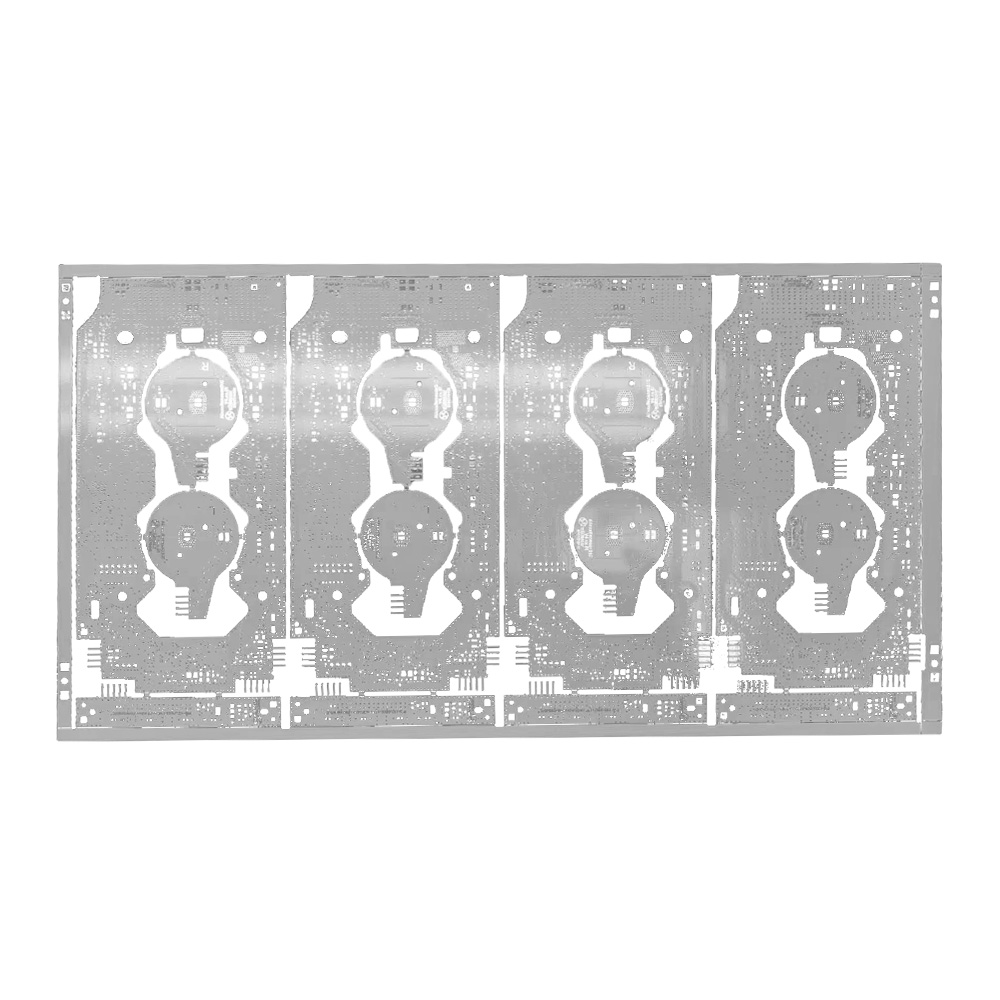

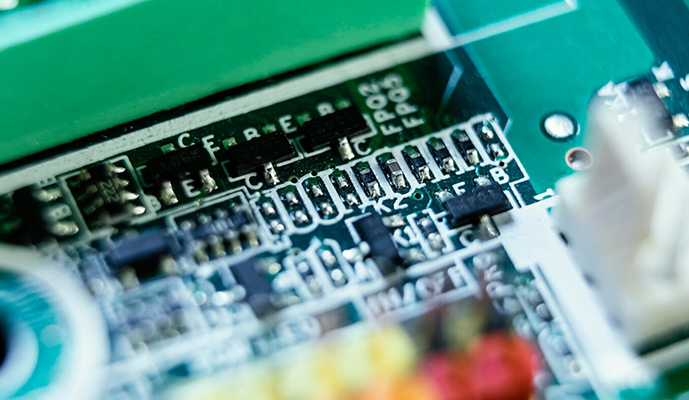

The core material of the circuit board (FR-4, high TG, halogen-free, high frequency) is made of grade A materials, which eliminates defective products from the source, ensures product quality, and strictly controls the production process in accordance with international PCB quality system standards.

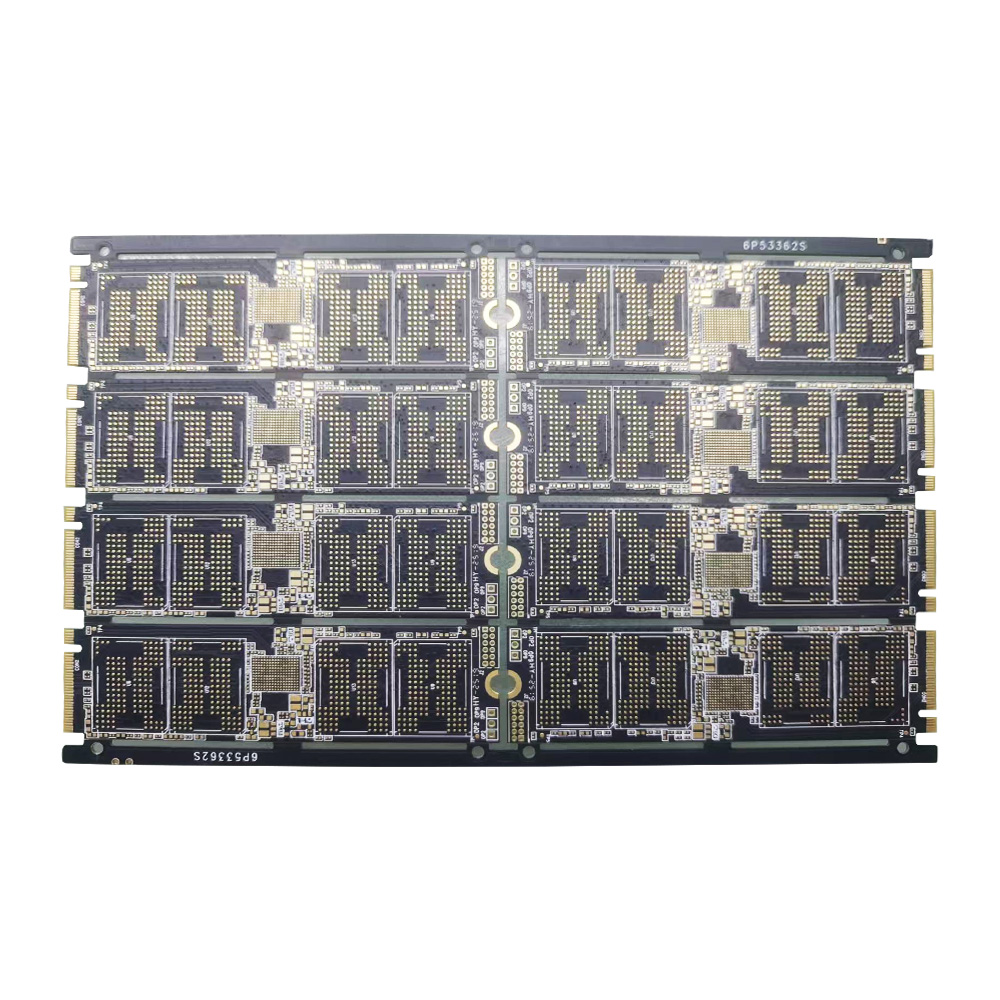

A full set of automated production equipment, real-time data control throughout the process, effectively guarantees on-time delivery, and on-time delivery to meet your R&D test requirements. There are also laser drilling machines, fully automatic screen printers, high-precision etching lines, copper thickness measuring instruments and other equipment to protect the production and quality of PCBs.

It meets the special process requirements of tin spraying, gold plating, nickel-palladium-gold, silver plating and other special processes. The whole process is tested layer by layer in 36 processes to ensure the safety of PCB board products through ULISO9001, CIC quality management system certification, etc. The qualified rate of finished products is more than 99%, ensuring quality first.

19 years of PCB manufacturing experience, 100+ online and offline teams, precise ERP management system and self-developed ICP CAM software, one-stop production from cutting to finished product shipment, eliminating the intermediate outsourcing links, reducing costs, efficient procurement, you only need to wait for delivery, and leave the rest to me!

PCB design and manufacturing software are essential tools used to create printed circuit boards, which are the backbone of most electronic devices. These software platforms allow engineers and designers to design circuits, layout the board, and prepare it for manufacturing. They typically include features like schematic capture, PCB layout, auto-routing, and simulation, enabling users to visualize and test their designs before production.

Original electronic products companies can’t do without contract electronic manufacture service providers these days. These service providers allow electronic products companies to focus all their energy in the development of the company, procuring clients and more orders and managing employees and other aspects, without worrying about the electronic assembling part of their business.

Moisture is the most common and most destructive factor for the PCB circuit board. Excessive moisture can greatly reduce the insulation resistance between the conductors, accelerate the high-speed decomposition, reduce the Q value, and corrode the conductor. We often see that the metal part of the PCB circuit board has been caused by the chemical reaction of the metal and copper with the water vapor and oxygen.